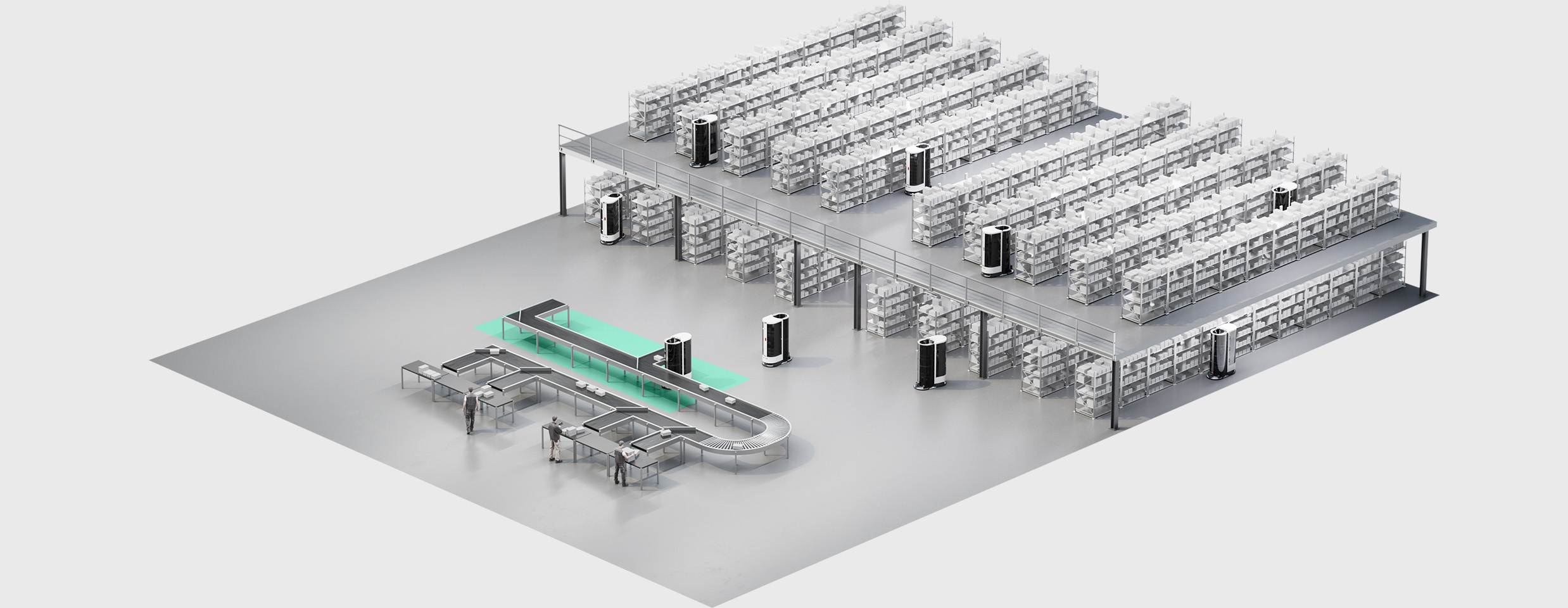

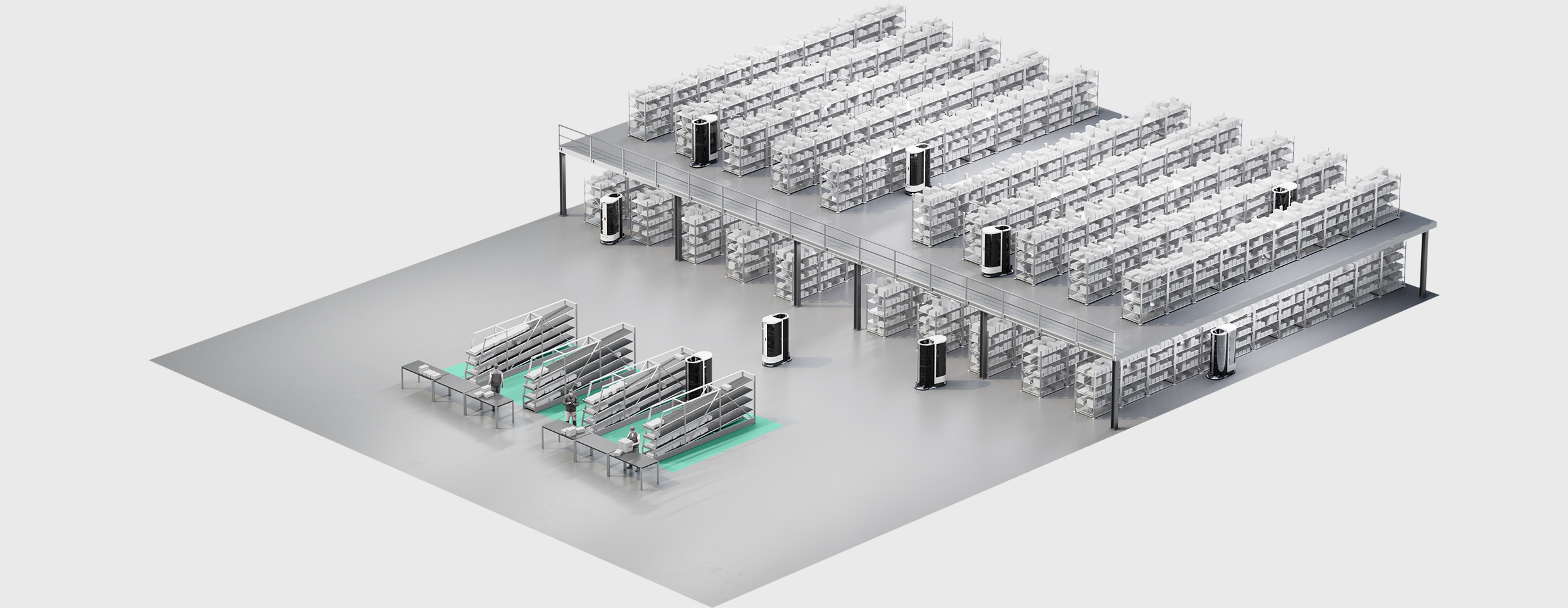

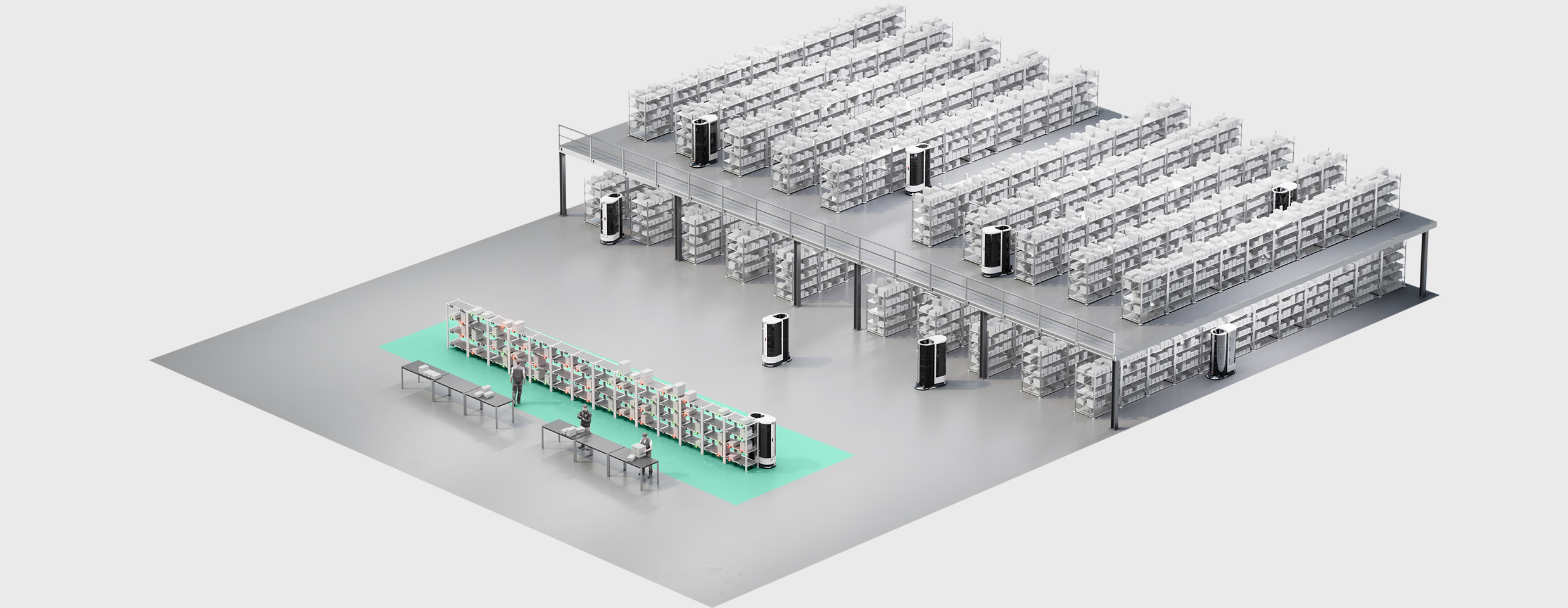

TORU integrates easily and without major adjustments into an existing warehouse and processes. Once configured, it works autonomously alongside its human colleagues. The connection to a warehouse management system is uncomplicated via WLAN.

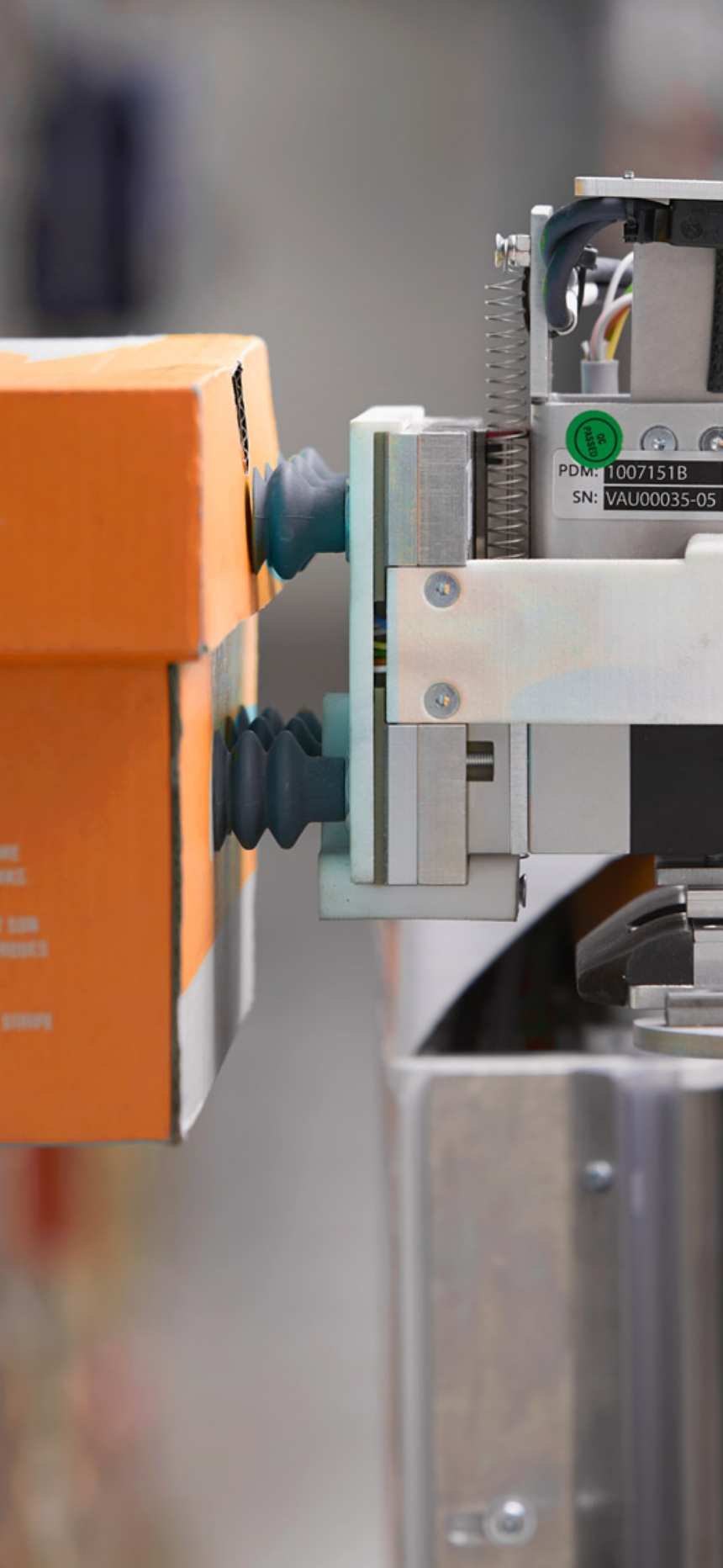

Shoe boxes are its speciality: the intelligent picking robot TORU picks up individual boxes and takes them directly to the transfer station. And for putaways or returns? Back again. Up to 20 hours per day. This allows it to be active outside regular shift times and, for example, to smooth out peaks through preparatory work.

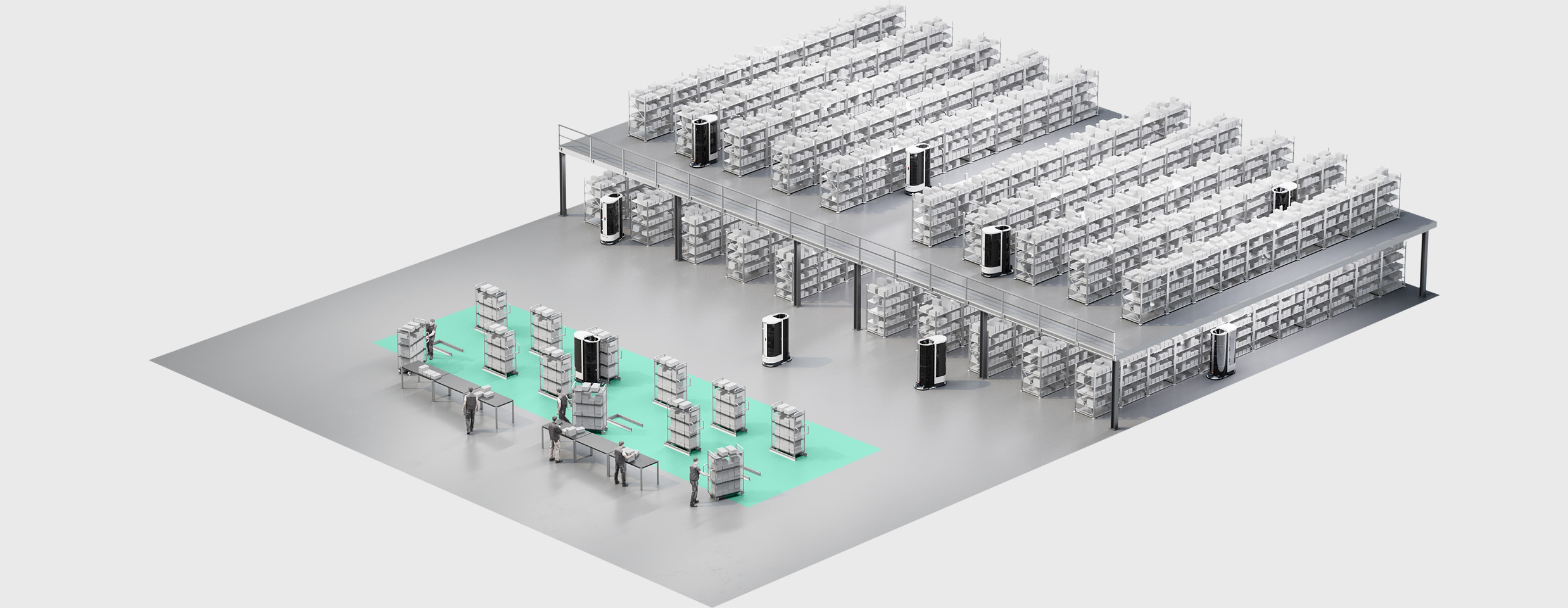

Order picking with TORU not only adapts to the environment, but also to increasing demand. New robots can be integrated directly, so your fleet grows with your success.

TORU integrates easily and without major adjustments into an existing warehouse and processes. Once configured, it works autonomously alongside its human colleagues. The connection to a warehouse management system is uncomplicated via WLAN.

Shoe boxes are its speciality: the intelligent picking robot TORU picks up individual boxes and takes them directly to the transfer station. And for putaways or returns? Back again. Up to 20 hours per day. This allows it to be active outside regular shift times and, for example, to smooth out peaks through preparatory work.

Order picking with TORU not only adapts to the environment, but also to increasing demand. New robots can be integrated directly, so your fleet grows with your success.

With ARC (Advanced Robot Control), users always have an overview of the entire fleet, the individual robot as well as the order management and relevant KPIs.

The TORU mobile robot is ideal for sorting orders into dedicated compartments as well as picking up boxes for the putaway process. It picks up individual boxes and transports them to a transfer point. Here, TORU can consolidate different items according to order so that the packaging process can be triggered directly.

Control of the robot fleet

ARC is the control center of the TORU fleet and is connected to the inventory management system. On a day-to-day basis, ARC not only offers full transparency of all robots, order management and KPIs, but also provides instructions on how to solve problems.

Visual Representation

The visual map display in your own warehouse makes controlling the fleet particularly intuitive. It shows where the individual robots are on the move in the warehouse, which orders they are processing, which items they are currently transporting and which actions are coming up next.

Tracking of KPIs

Relevant KPIs are recorded in real time and clearly displayed. The data overview offers full transparency at all times. For example, fleet performance over a period of time, average utilization or the current status of the transfer stations.

Order Management

Order management ensures optimal structuring of transport orders to guarantee a fast process. Current orders are distributed in the fleet and can be read at any time.

Human Process Coordination

ARC also coordinates the processes between robots and humans. Employees can see directly which picking trolley is ready for pick-up.

Remote Operations

The remote operations team monitors robot activities 24 hours a day, 6 days a week, and can proactively assist remotely if needed, increasing fleet availability.