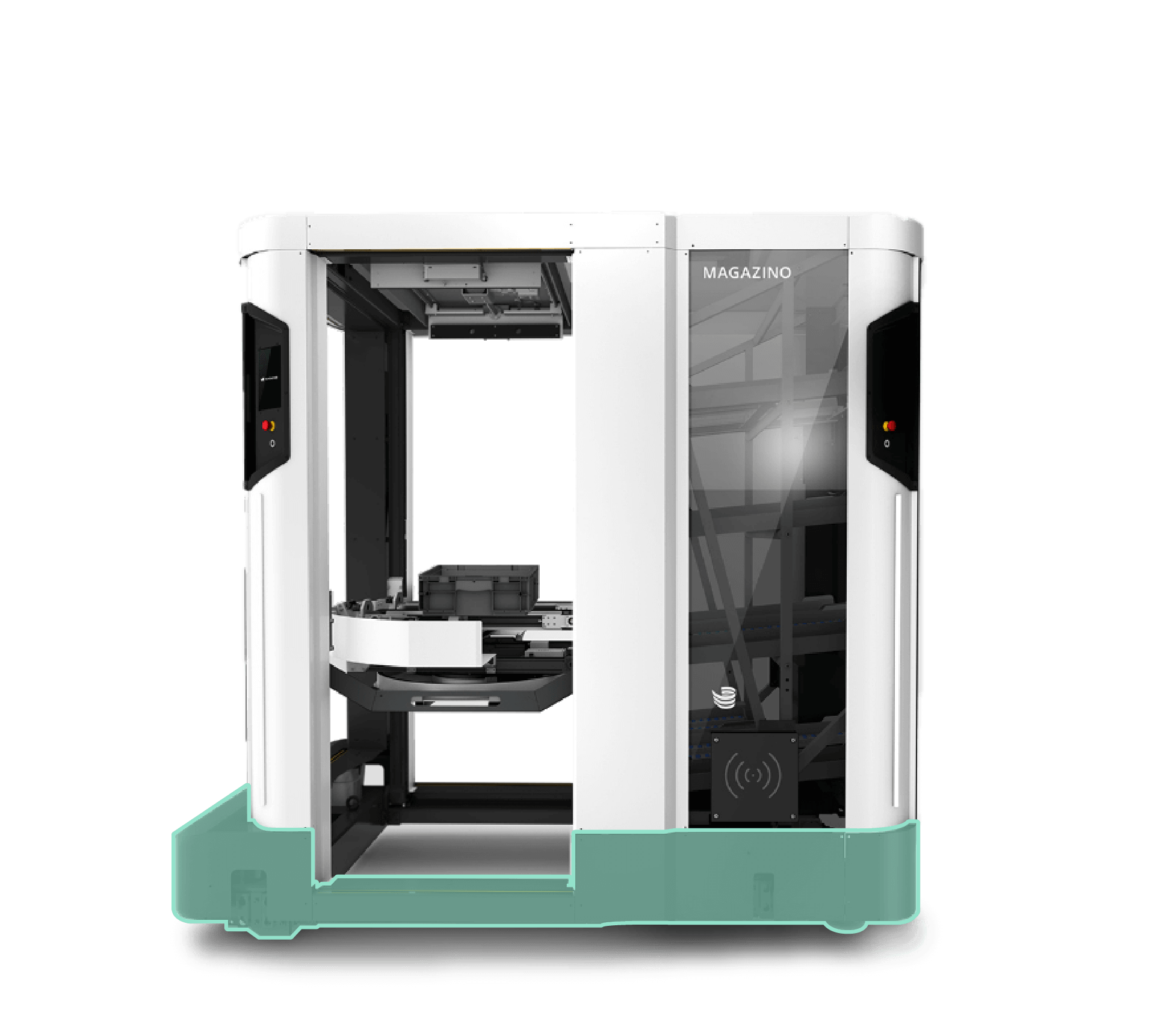

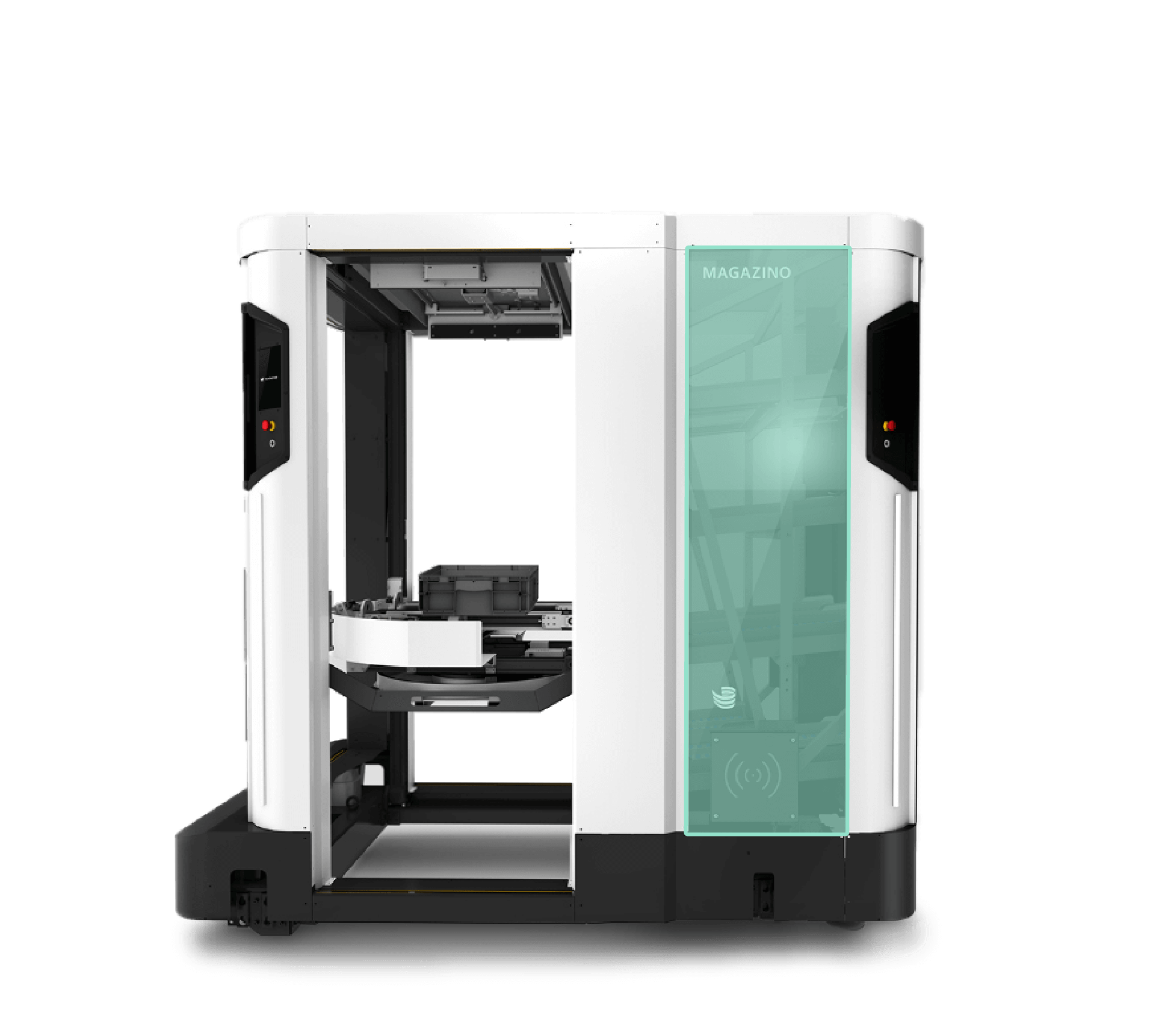

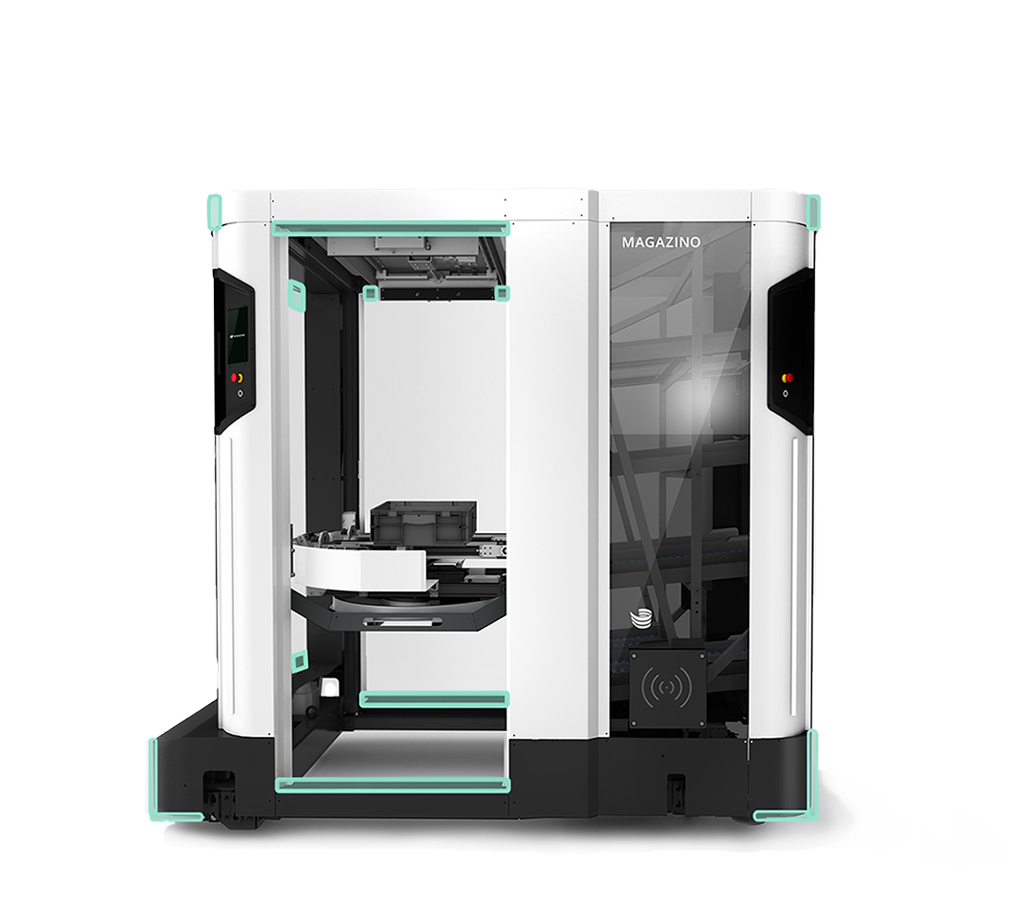

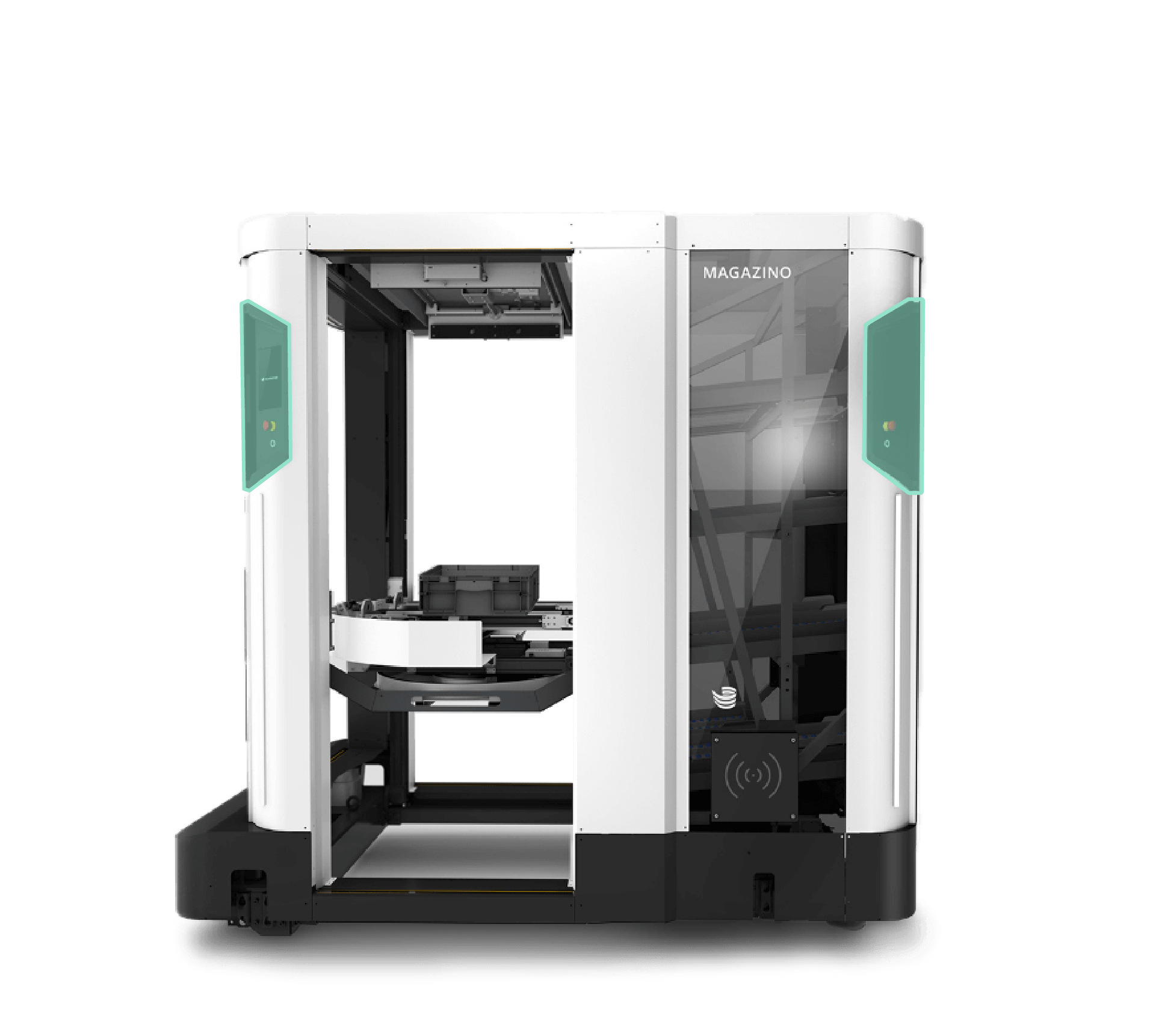

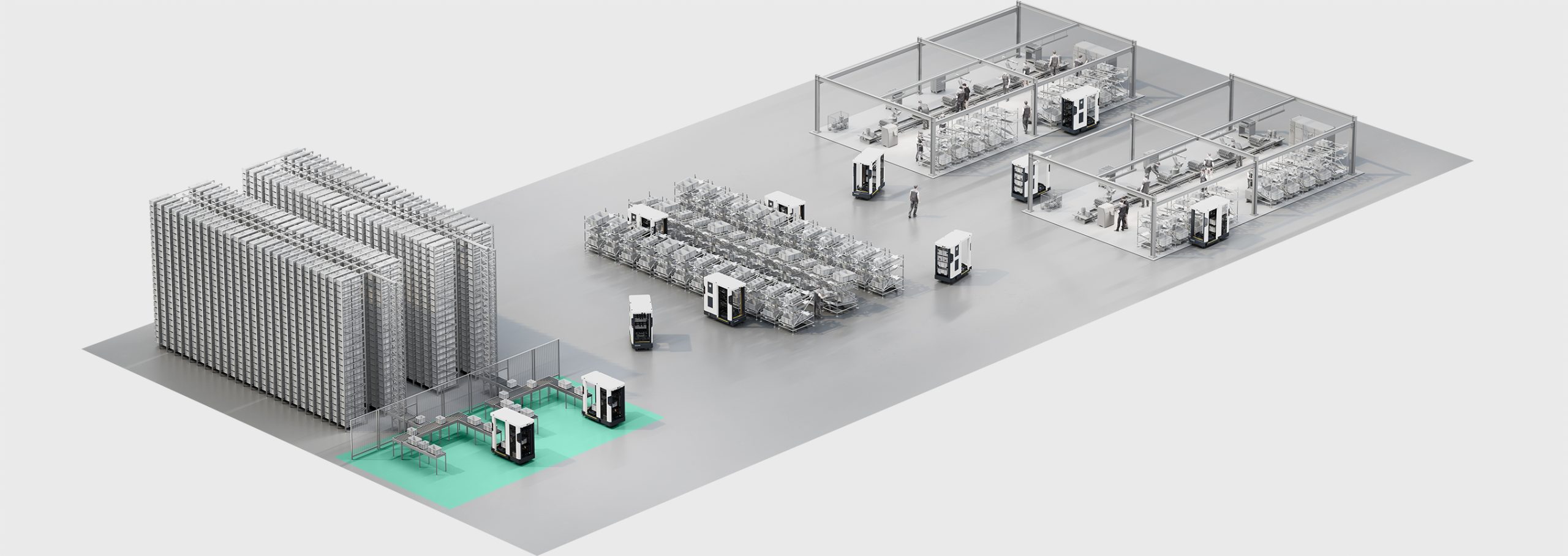

Until now, production logistics have been carried out almost exclusively manually. Driverless transport systems have driven automation forward. SOTO goes one step further and brings materials directly to the assembly line, just-in-time and at different heights directly to the target compartment — completely autonomously. The initial setup is user-friendly and can be set up largely independently.

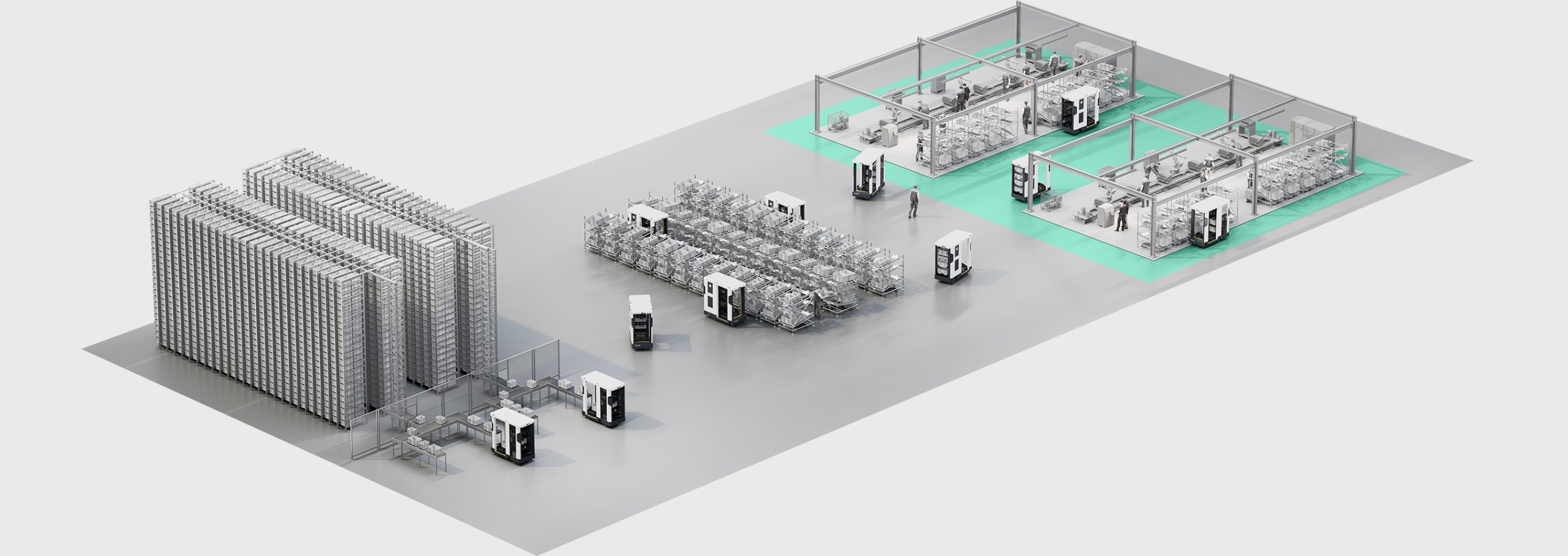

SOTO works up to 20 hours per day and enables processes that are not only more efficient but also significantly more cost-effective. Its operation is deliberately simple and enables parallel operation with humans. The hardware is extremely robust and designed for maximum reliability. You can rely on that.

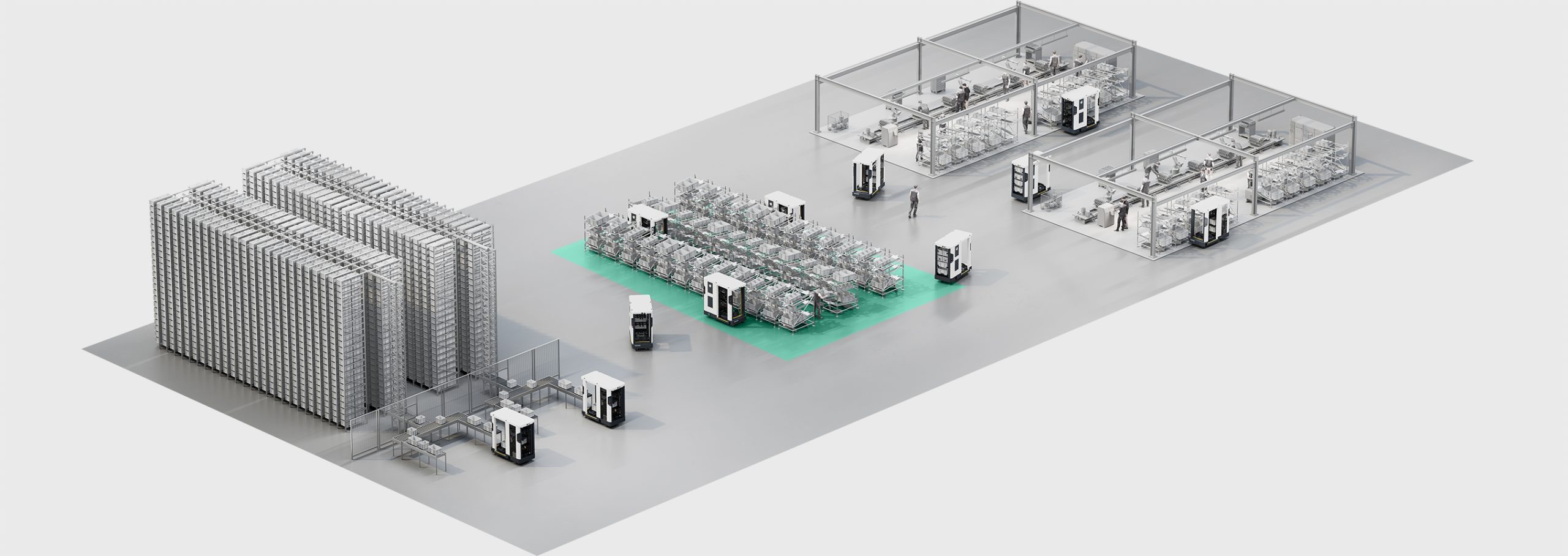

Material flow automation with SOTO not only adapts to the environment, but also to increasing demand. New robots can be integrated directly, so your fleet grows with your success.

Until now, production logistics have been carried out almost exclusively manually. Driverless transport systems have driven automation forward. SOTO goes one step further and brings materials directly to the assembly line, just-in-time and at different heights directly to the target compartment — completely autonomously. The initial setup is user-friendly and can be set up largely independently.

SOTO works up to 20 hours per day and enables processes that are not only more efficient but also significantly more cost-effective. Its operation is deliberately simple and enables parallel operation with humans. The hardware is extremely robust and designed for maximum reliability. You can rely on that.

Material flow automation with SOTO not only adapts to the environment, but also to increasing demand. New robots can be integrated directly, so your fleet grows with your success.

The Magazino Fleet Manager offers full transparency in the operation of the robot fleet and the process performance at a glance. Adaptation to changing environments is possible at any time.

The SOTO fleet closes the gap between automated warehouses and an automated production line. With its high intelligence, SOTO is able to perform complex transport tasks independently, reacting to changes in the environment and changing demand. It can completely replace route trains or also cooperate with them in a meaningful way.

Mapping

Initially, the robot learns its new environment for the first time by means of sensors and creates a map for future orientation. This happens playfully, with a controller, like gaming.

3D Environment Editor

The transfer stations for the KLTs are recorded three-dimensionally and displayed in the Fleet Manager in a user-friendly way. Environment-specific traffic rules are also created in the process. All environment parameters can be adjusted by the customer at any time.

Operation & Controlling

Keep track of robot operations at all times, with complete data transparency and a clear overview of material flows. See all relevant KPIs of your process directly at a glance.

Order Management

Order management ensures optimal structuring of transport orders to guarantee a fast process. Current orders are distributed throughout the fleet and can always be read in the Fleet Manager.

Multi-robot coordination

Thanks to the intelligent coordination of the Magazino Fleet Manager, SOTO robots work well together as a team. In the process, the Fleet Manager ensures optimal utilization of the individual robots and that they do not get in each other’s way.

VDA5050 Native

SOTO speaks VDA5050. This makes it the ideal supply robot for heterogeneous fleets in complex production environments. The simple integration into VDA5050 control systems enables communication with other logistics vehicles.