Attention to detail, constant striving for further development and the implementation of the latest innovations in the retail trade position the traditional company LLOYD as a pioneer in the identification and fulfillment of current customer requirements.

Magazino develops and builds perception-controlled, mobile robots. As the largest Advanced Robotics team in Europe, we revolutionize the world of intralogistics together with our customers.

State-of-the-Art in intralogistics

LLOYD Shoes GmbH has stood for the highest quality in shoe production since 1888. Founded by H. F. Meyer in Bremen, Germany, LLOYD is expanding worldwide and is now established internationally through the LLOYD Concept Stores and therefore personally available to customers in various regions. LLOYD currently sells its products, which are available in more than 56 countries worldwide, at around 3,350 points of sale. In 2018, LLOYD Shoes GmbH employed an average of 1,792 people, 715 of them in Germany alone.

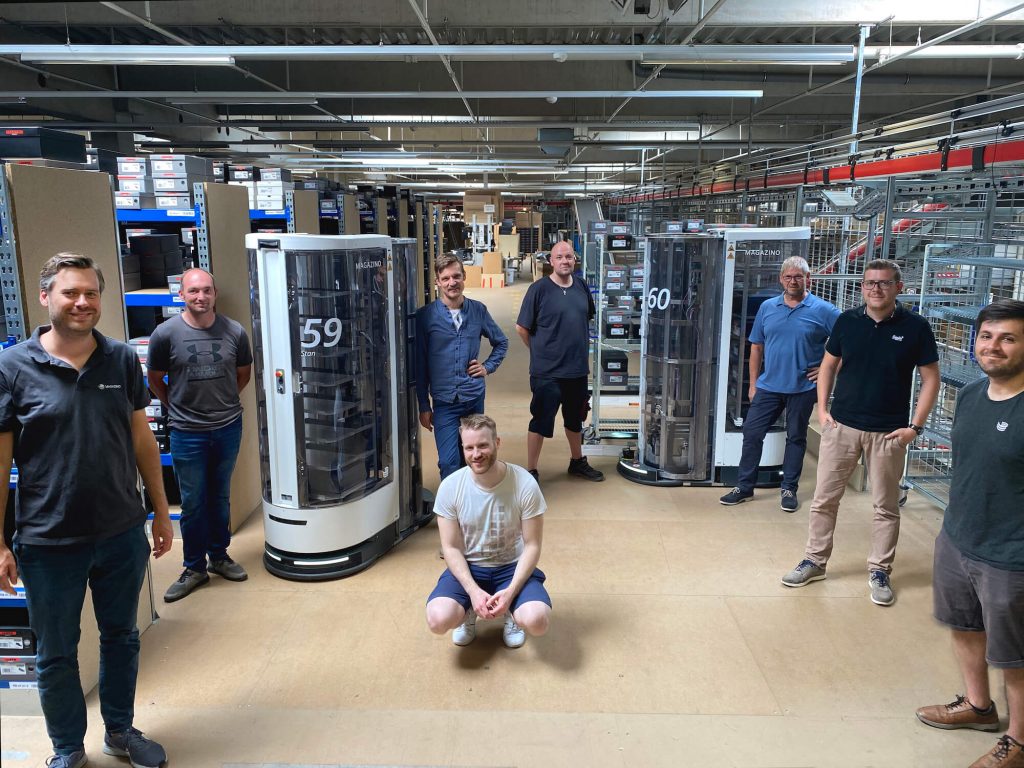

In December 2019 the first two mobile picking robots were delivered from Magazino to Sulingen, the headquarters of LLOYD. From here, the distribution for LLOYD’s 28 concept stores worldwide as well as for LLOYD’s online business is handled. The TORU robots autonomously store and pick shoes in the shelving systems over an area of around 700 square meters. TORU can work alongside humans and therefore provide active support, especially during order peaks and at peripheral times. Laser scanners and numerous sensors on the robots ensure that working together in the same rack corridor is safe for man and machine.

In the inbound process, the items to be stored are taken over by TORU from a shelf rack. In the outbound process, the picked shoeboxes are transferred both in picking carts, which are positioned at the ends of the shelf rows, and in shelves next to the packing stations.

What made the project special, was the outbreak of the Corona pandemic in spring 2020, which interrupted the integration of the robots into the ongoing operation for several months. The success was even more remarkable when in August 2020 the integration of the robots was completed in record time, despite numerous restrictions due to the pandemic, and all acceptance criteria were met. The operation of the robots was then completely handed over to LLOYD employees — since then, the robots have been working autonomously on a daily basis and are supported in rare exceptional cases via remote support from Munich or, if physical intervention is necessary, by a trained LLOYD employee.

With the use of the intelligent robots, LLOYD is one of the innovative pioneers in the industry. This is because the continuing growth in online trade and ever smaller batch sizes, even in stationary retail, require automation solutions that can be flexibly adapted and scaled as required. Additional TORU robots can be integrated into an existing fleet in a few hours.

Robots in operation