Meyer & Meyer uses Magazino robots in shoe warehouse

Press releases

19. April 2018

Share

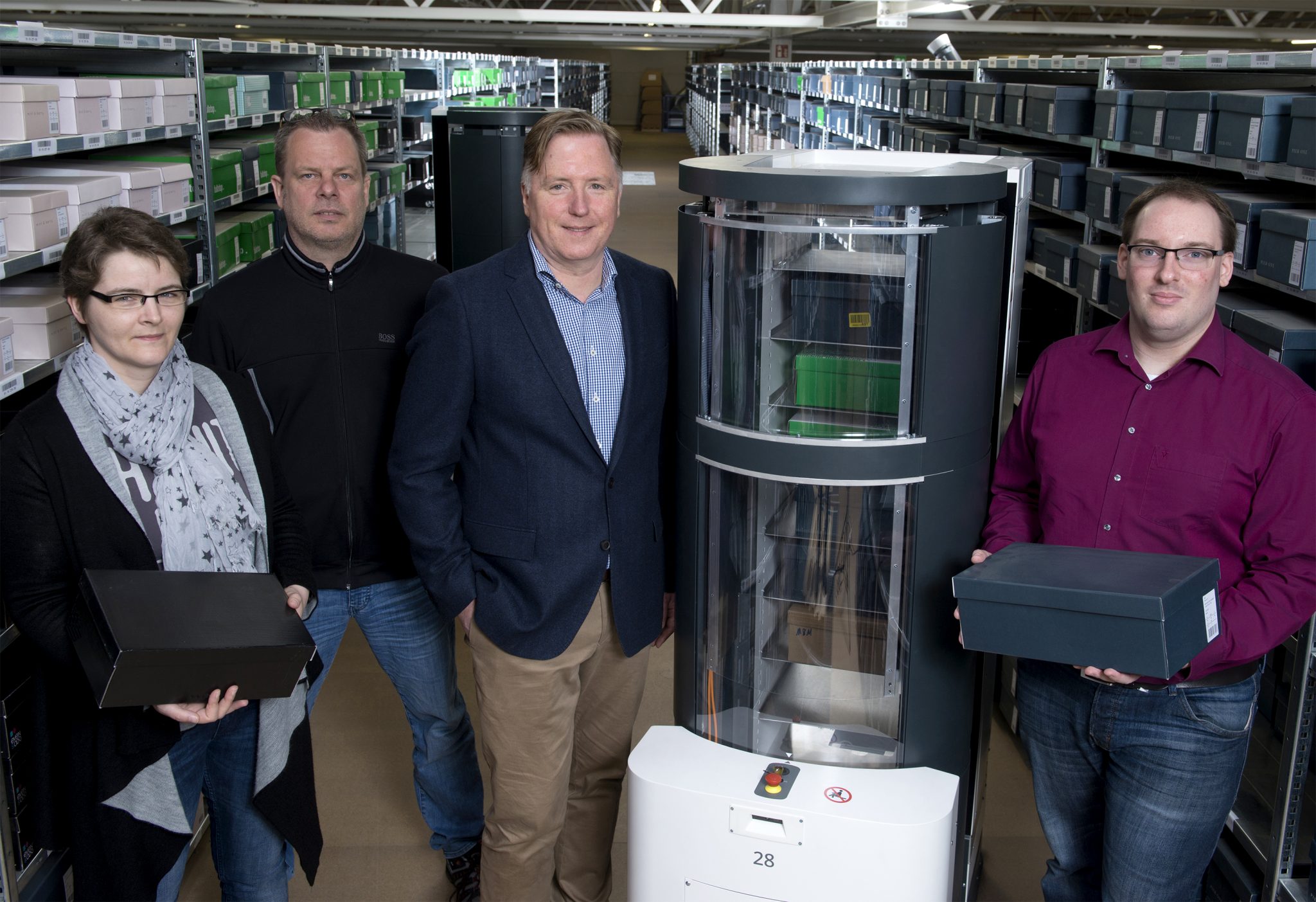

The Osnabrück-based fashion logistics specialist Meyer & Meyer is using two modern picking robots for carton handling in its halls for the first time. The robots are part of the company’s continuous innovation and automation efforts. Since April 2018, the modern new technology has been supporting the smooth and error-free storage and retrieval of shoe cartons for the customer zLabels at the location Peine.

The technology partner for the project is the experienced Munich robotics manufacturer Magazino. The company develops and builds perception-controlled, mobile robots for intralogistics. The technology used enables piece-accurate access to individual objects and thus automated handling of shoe cartons. “Our goal is the continuous optimization of all our supply chain services for our customers. The use of innovative technology is very important to us,” says Marcus Reibetanz, Director Logistics Planning & Development. “We are pleased that we have found a long-term partner in Magazino who enables us to use the latest robotics technology in various application scenarios”.

The robots in detail

The picking robot with the name TORU is one of the first perception-controlled robots on the market that not only control autonomous transport, but also reach into the shelves. This makes the picking principle pick-by-robot possible for the first time. Using numerous 3D cameras, sensors and laser scanners, the robots can perceive and interpret their surroundings and thus act independently and make decisions. With its 3D camera, for example, TORU always first looks at the shelf in order to record the exact position and dimensions of a shoe box — based on this, the gripping process is then planned and executed in fractions of a second. TORU receives its work orders via a WLAN connection to the merchandise management system. In addition, the robots can network, exchange experiences with complex situations and thus learn from each other.

Meyer & Meyer expects a variety of advantages from the use of the robots. These include, for example, additional off-hour activities such as pre-order picking overnight or inventory support. Further advantages result from the high flexibility of the location-independent robots and the support during ergonomically particularly challenging picking processes, for example picking from the top or bottom level of a shelving rack. From September 2018, Meyer & Meyer plans to use an additional SOTO robot for cartons up to 60x40x40 cm and a maximum weight of 15 kg. “We consider robotic solutions to be an essential component of future-proof intralogistics and fulfillment solutions,” says Marcus Reibetanz.

About Meyer & Meyer

The Osnabrück-based family business Meyer & Meyer is an experienced partner of the fashion industry and accompanies its customers along the entire supply chain — from sheep to shop. As the leading specialist for fashion logistics in Europe, the company offers a range of services from raw materials and production logistics to storage, processing and quality assurance to the ready-for-sale distribution of goods to retailers or end customers. Meyer & Meyer controls and links value chains using state-of-the-art IT technologies and offers intelligent omnichannel solutions together with partners. In addition to fashion logistics, Meyer & Meyer has developed further specific logistics solutions for the automotive industry and various particularly sensitive goods. Meyer & Meyer controls logistics activities in Europe, Asia and North Africa with 1,800 employees from its headquarters and a network of branches and partner companies in Germany and abroad.

Magazino develops and builds perception-controlled, mobile robots. As the largest Advanced Robotics team in Europe, we revolutionize the world of intralogistics together with our customers.

more