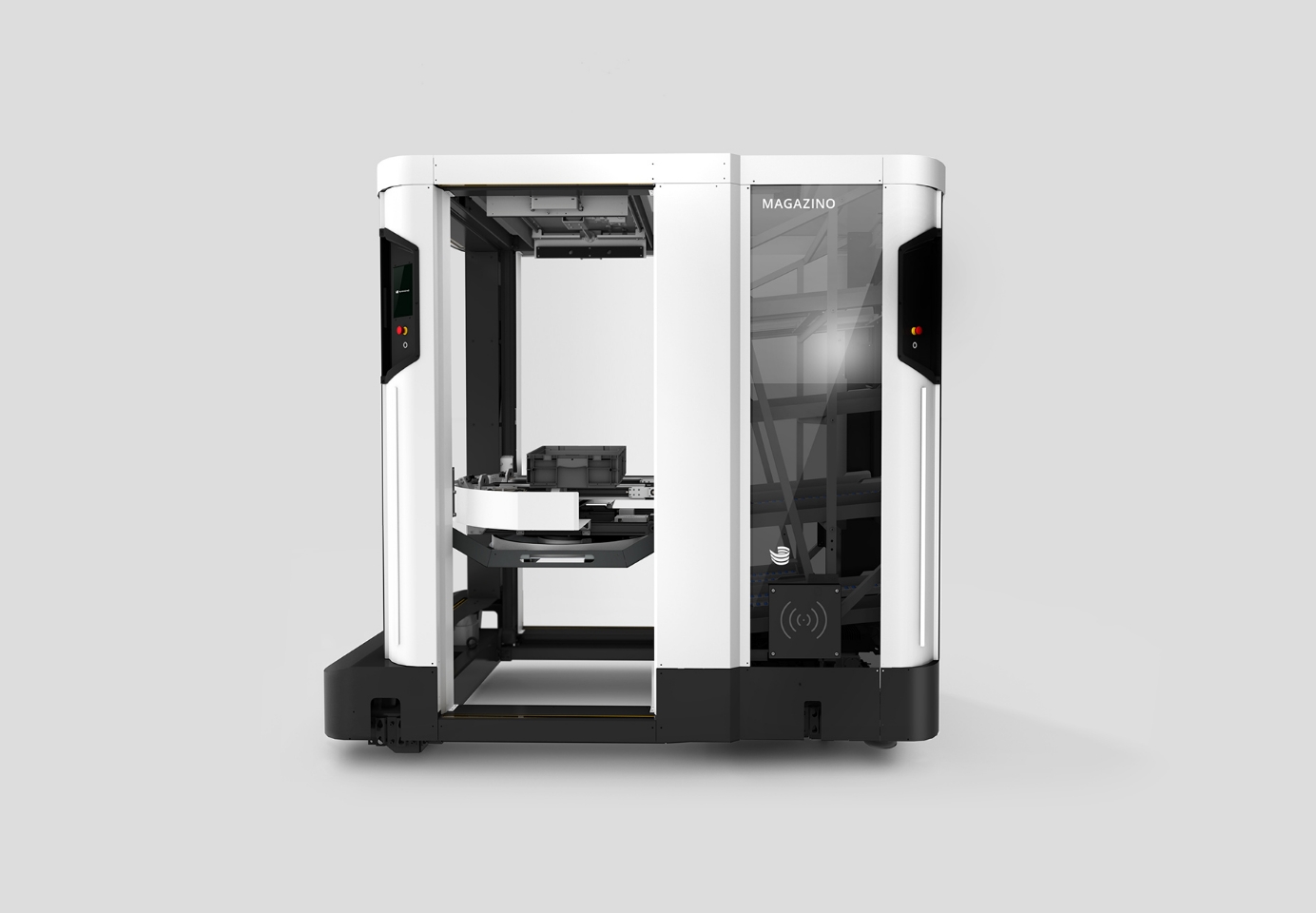

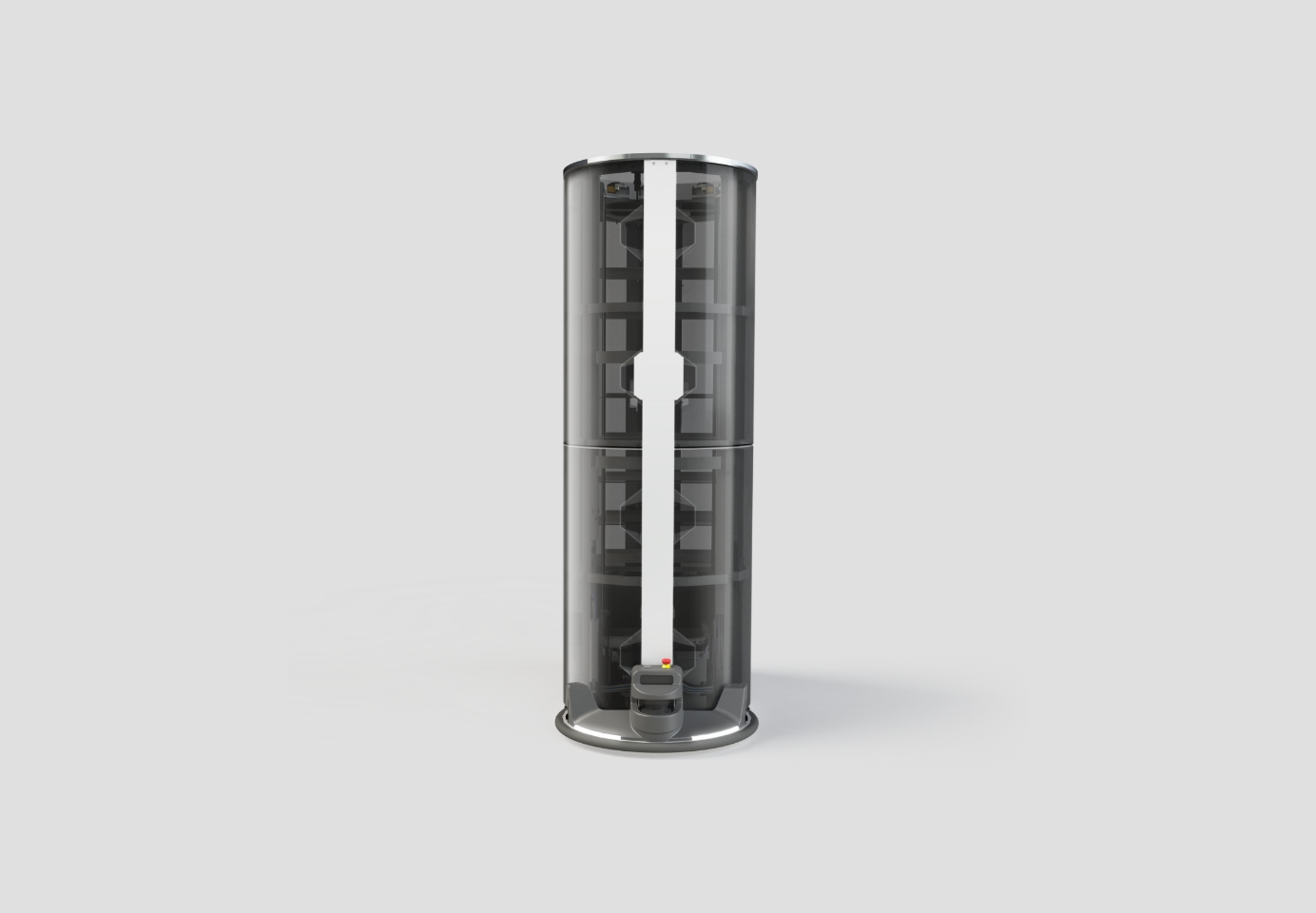

Magazino works on the development and implementation of intelligent intralogistics. By combining mobile robots and our ACROSAI technology, we create logistics processes that set new standards in terms of flexibility and efficiency.

Experience automation and autonomy in harmony.

22.02.2024

MAN automates production logistics with 12 Magazino SOTO robots

Magazino wins MAN’s Nuremberg site as a fleet customer for the SOTO robot. more ›

23.08.2023

Jungheinrich acquires all shares in robotics company Magazino from the founders and previous co-shareholders

Hamburg-based intralogistics pioneer Jungheinrich is fully taking over Magazino, a Munich-based robotics specialist. more ›

18.04.2023

CLS iMation expands its portfolio of solutions with Magazino, revolutionising robotics for site logistics processes

Developing a range targeted at constant innovation of logistics processes in an Industry 4.0 framework, CLS iMation has further strengthened its portfolio of services with solutions from Magazino, a German company specialised in the development of smart robots that offer safe and autonomous operational support. more ›