Zalando tests logistics robot TORU in Erfurt, Germany

Press releases

26. October 2018

Share

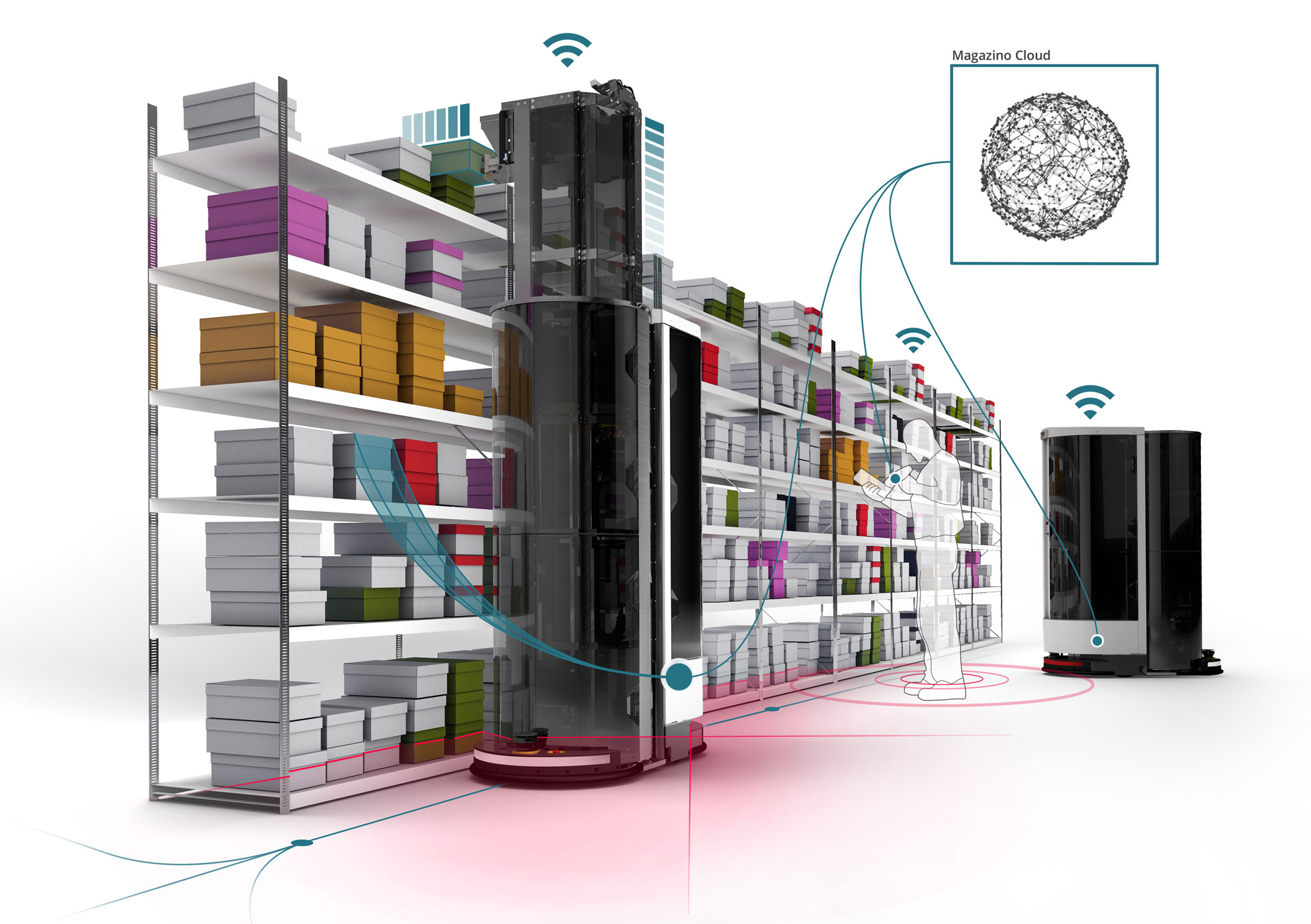

Munich, 26.10.2018 | Zalando is currently testing how robotics can be used intelligently in logistics. At the end of February 2018, Zalando acquired shares in startup Magazino, which develops robots for intralogistics. Two robots developed by Magazino under the name “TORU” have been undergoing practical testing at Zalando in Erfurt for several weeks now: Until May, the robots will be integrated into the processes and provide support in the areas of “Stow”, i.e. storage, and “Pick”, i.e. order picking. What’s special: In contrast to other automation technologies, where only entire load carriers such as pallets or crates can be moved, the TORU robots have intelligent camera technology and can thus recognize, pick and transport individual objects. They thus fit into the chaotic warehousing system used in Zalando’s logistics centres.

Carl-Friedrich zu Knyphausen, Head of Logistics Development at Zalando, is responsible for the further development of intralogistics and accompanied the TORU robots in their first steps. He tells us more about the possibilities and challenges of using the new technology.

Carl-Friedrich, what are the advantages of the TORU robot and what does Zalando use it for?

CFK: TORU is an autonomous robot that perceives its environment through the built-in cameras, can orient itself and work next to humans. We are currently testing how we can use it as an autonomous picking robot, i.e. in stow and pick, integrate it into our existing processes and support our employees. The idea is that it relieves logistics employees of unergonomic activities such as bending down and stretching far up when picking products from the highest or lowest shelf levels. However, TORU is currently only able to pick cartons, usually shoes.

However, we are still in test operation, which means that the majority of test orders are placed with Magazino robots. Yet the robots have already processed the first customer orders. When a robot receives an order, it designs the best route with its own navigation system. Together with Magazino, we are working to make TORU better and faster.

How does the robot interact with humans?

CFK: The robot sees when a human wants to cross its path and waits accordingly before continuing with its task. So TORU drives to the shelves in the picking area and processes its picking list, just like the employee does. With integrated cameras and scanners, TORU identifies and locates the right items on the shelf, takes them off the shelf with its suction pad, stows them in its backpack and then drives to the transfer station to put them away.

How does the Magazino robot test fit into the Zalandos logistics strategy?

CFK: Since the construction of our first logistics centre in Erfurt in 2012, we have been investing in automation. Even during the development of our conveyor technology, the focus was on the technology bringing the products to our employees, thus saving them walking distances and relieving them. Another example is our bag sorters in Mönchengladbach and Lahr, which relieve our colleagues of unergonomic movements. The prospects for TORU could be similar, but this will take some time. Investing in automation and testing robotic solutions is therefore the next logical step for Zalando and our logistics strategy.

What can we expect from logistics automation in the future?

CFK: We will continue to test different technologies until we have found exactly the right solution for us, as we did for the bag sorters Lahr and Mönchengladbach. Zalando wants to further promote the use of technology in logistics and advance the industry in this respect. The exchange with our partners and colleagues in the industry is very important for this. On Thursday, 25 October, we met at our logistics centre in Erfurt at the Magazino expert panel with over 40 representatives of successful e‑commerce companies and logistics service providers and discussed the use of new technologies. A key question in the various workshops was how machines can support people in the future. I can imagine that technology will increasingly be used to help manual processes in the future as well, since factors such as increasing demands on ergonomics and occupational health and safety will drive their use.

About Zalando

Zalando is Europe’s leading online platform for fashion and lifestyle. We offer our customers a comprehensive selection of clothing, shoes, cosmetics and accessories for women, men and children free of charge and return shipping. The assortment ranges from almost 2,000 world-famous brands to local and fast-fashion brands and self-designed private labels. The Zalando shops are locally tailored to the needs of customers in 17 different European markets: Austria, Belgium, the Czech Republic, Denmark, Finland, France, Germany, Ireland, Italy, Luxembourg, the Netherlands, Norway, Poland, Spain, Sweden, Switzerland and the United Kingdom. Zalando’s logistics network with five central logistics centres enables efficient delivery to all customers throughout Europe, supported by locations in Northern Italy, France and Sweden focused on local customer needs. We are convinced that the triad of fashion, technology and logistics offers added value to our customers and brand partners.

Magazino develops and builds perception-controlled, mobile robots. As the largest Advanced Robotics team in Europe, we revolutionize the world of intralogistics together with our customers.

more